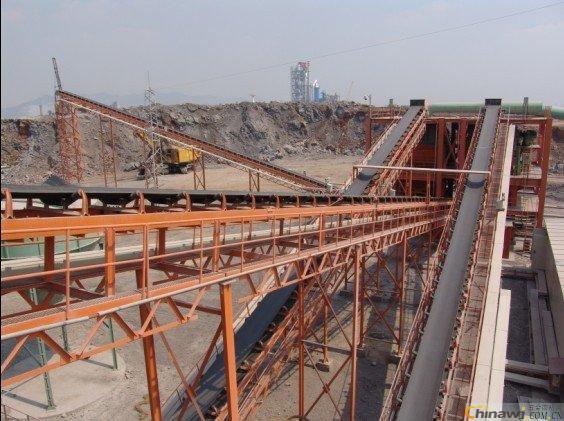

Belt conveyors

Belt conveyor is a friction-driven machine that transports materials in a continuous manner. It is mainly composed of a frame, conveyor belt, roller, drum, tensioning device, transmission device, etc. It can form a material conveying process from the initial feeding point to the final unloading point on a certain conveying line. It can convey both bulk materials and finished items. In addition to pure material transportation, it can also cooperate with the requirements of the process in the production process of various industrial enterprises to form a rhythmic flow operation transportation line.

Belt conveyor is also called belt conveyor. The conveyor belt moves according to the principle of friction transmission. It is suitable for conveying low-abrasive materials and bagged materials with a bulk density of less than 1.67/ton/cubic meter, which are easy to take out, such as coal, gravel, sand, cement, fertilizer, grain, etc. Belt conveyor can be used in the ambient temperature range of -20℃ to +40℃, and the temperature of the conveyed material is less than 60℃. Its length and assembly form can be determined according to user requirements. The transmission can be an electric roller or a drive device with a drive frame.

Working principle

The belt conveyor is mainly composed of two end rollers and a closed conveyor belt tightly sleeved thereon. The roller that drives the conveyor belt to rotate is called the drive roller (transmission roller); the other roller that only changes the direction of movement of the conveyor belt is called the redirection roller. The drive roller is driven by an electric motor through a reducer, and the conveyor belt is dragged by the friction between the drive roller and the conveyor belt. The drive roller is generally installed at the discharge end to increase the traction force and facilitate dragging. The material is fed from the feeding end and falls on the rotating conveyor belt. It is driven by the friction of the conveyor belt and transported to the discharge end for discharge.

Other instructions

1. The belt conveyor should be supervised by a fixed person during operation. The supervisor must have general technical knowledge and be familiar with the performance of the conveyor.

2. The enterprise should formulate the "equipment maintenance, inspection, and safe operation procedures" for the conveyor so that the supervisor can follow them. The supervisor must have a shift system.

3. Feeding the belt conveyor should be uniform, and excessive feeding should not be allowed to fill the feed funnel with materials and overflow.

4. During the operation of the conveyor, non-supervisory personnel should not approach the machine, and no personnel should touch any rotating parts. In case of a fault, the operation must be stopped immediately and the fault must be eliminated. If there are defects that are not easy to eliminate immediately but do not have a great impact on the work, they should be recorded and eliminated during maintenance.

5. When supervising the conveyor, the operation of each component should be observed frequently, and the connecting bolts should be checked at various locations. If they are found to be loose, they should be tightened in time. However, it is absolutely forbidden to clean and repair the running parts of the conveyor when the conveyor is running.

6. The spiral tensioning device assembled at the tail should be adjusted appropriately to keep the conveyor belt with normal working tension. The supervisor should frequently observe the working condition of the conveyor belt. For the partially damaged parts, it should be decided whether to replace them immediately or replace them with new ones during maintenance depending on the degree of damage (i.e. whether it affects production). The dismantled conveyor belt should be used for other purposes depending on the degree of wear.

7. When taking care of the belt conveyor, it is necessary to observe its working status, clean, lubricate, check and adjust the spiral tensioning device and other sporadic work.

8. Under normal circumstances, the belt conveyor should be started when there is no load and stopped after the material is unloaded.

9. In addition to maintaining normal lubrication and replacing individual damaged parts during use, the conveyor must be fully overhauled every 6 months of operation. During the overhaul, the defects in use and records must be eliminated, damaged parts must be replaced, and lubricants must be replaced.

10. The enterprise can formulate the overhaul cycle according to the working conditions of the conveyor.